Primary Injection Tester

June Company’s repair and calibration process for primary injection testers begins with meticulous diagnosis of issues. Technicians thoroughly inspect components like current injectors, sensors, and control circuits to identify faults or inaccuracies. Each component, including the current source, control electronics, and measurement systems, undergoes comprehensive evaluation for signs of wear, damage, or malfunction. Faulty components are repaired or replaced, including high-current injectors, sensors, connectors, and other electronic parts, to restore the tester’s functionality. The tester is recalibrated to industry standards for precise measurement and injection of high currents, ensuring consistent and reliable test results. Post-repair and calibration, the tester undergoes rigorous verification through various test scenarios to accurately inject high currents and measure the circuit breaker’s performance. Final testing confirms its performance and reliability, accurately verifying the protection chain of circuit breakers and effectively handling fault conditions. June Company’s meticulous approach ensures primary injection testers from all manufacturers operate with precision, maintaining the safety and efficiency of electrical systems.

Showing all 21 results

-

ISA eKAM Injection Test Set Repair

Read more -

SMC LET-1000-RD Primary Injection Meter Repair

Read more -

SMC LET-2000-RD Primary Injection Meter Repair

Read more -

SMC LET-2000-RDM Primary Injection Meter Repair

Read more -

SMC LET-2010-RD Primary Injection Meter Repair

Read more -

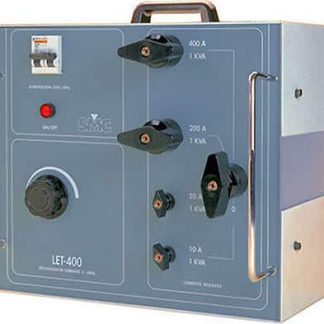

SMC LET-400 Primary Injection Meter Repair

Read more -

SMC LET-400-RD Primary Injection Repair

Read more -

SMC LET-400-RDC Primary Injection Repair

Read more -

SMC LET-4000-R Primary Injection Repair

Read more -

SMC LET-4000-RD Primary Injection Repair

Read more -

SMC LET-4000-RDM Primary Injection Meter Repair

Read more -

SMC Raptor C05 MS WA Primary Injection Repair

Read more -

SMC Raptor C15 MS SL Primary Injection Repair

Read more -

SMC Raptor C25 MS 2SL Primary Injection Repair

Read more -

SMC Raptor C35 MS 3SL Prime Rejection Repair

Read more -

SMC Raptor C45 MS 4SL Primary Injection Repair

Read more -

SMC Raptor CV05 MS HV Primary Injection Repair

Read more -

SMC Raptor CV15 MS HV Primary Injection Repair

Read more -

SMC Raptor-HV Primary Injection Repair

Read more -

SMC Raptor-SL Primary Injection Repair

Read more -

SMC TriRaptor 3MS Primary Injection Repair

Read more

Showing all 21 results