Description

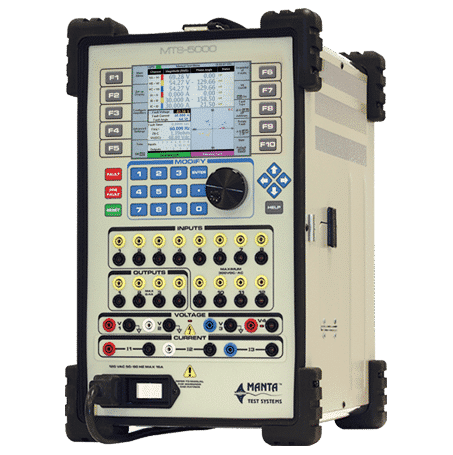

Manta MTS-5000 Relay Test System Repair & Calibration Services

June Company offers expert repair and calibration services for the Manta MTS-5000 Protective Relay Test System, ensuring precise voltage and current injection, accurate phase control, and reliable operation for protection relay testing. Whether your unit fails to power on, exhibits output inconsistencies, or encounters communication issues, our technicians are equipped to restore it to optimal performance.

We support Manta relay test systems utilized in substation maintenance, protection scheme verification, and IEC 61850 system diagnostics.

Common Manta MTS-5000 Issues We Repair

-

Failure to power on or complete initialization

-

Inaccurate or unstable voltage/current outputs

-

Phase angle or frequency control errors

-

Relay trip signal failures or misoperations

-

Communication port issues (USB, Ethernet, RS232)

-

Output channel malfunctions or connector damage

-

Internal power supply or control board faults

Our Repair & Calibration Process

Each MTS-5000 unit undergoes comprehensive diagnostics and performance verification:

-

Initial evaluation completed within 48 hours

-

Detailed inspection and cleaning of internal components

-

Repair or replacement of signal generators, amplifiers, and interface circuits

-

Functional testing with simulated relay conditions and fault scenarios

-

Optional NIST-traceable calibration certificate available upon request

Why Choose June Company?

-

Over 25 years of experience servicing relay test equipment and power system diagnostic tools

-

Trusted by utility engineers, commissioning teams, and testing laboratories

-

All repairs backed by a comprehensive 90-day warranty

-

Fast turnaround with detailed service documentation

-

Calibration-ready services to meet regulatory and quality assurance standards

Schedule Your MTS-5000 Repair Today

If your Manta MTS-5000 Relay Test System is experiencing performance issues or operational failures, June Company is here to assist.

📩 Contact us today to request expert evaluation, repair, and calibration services.